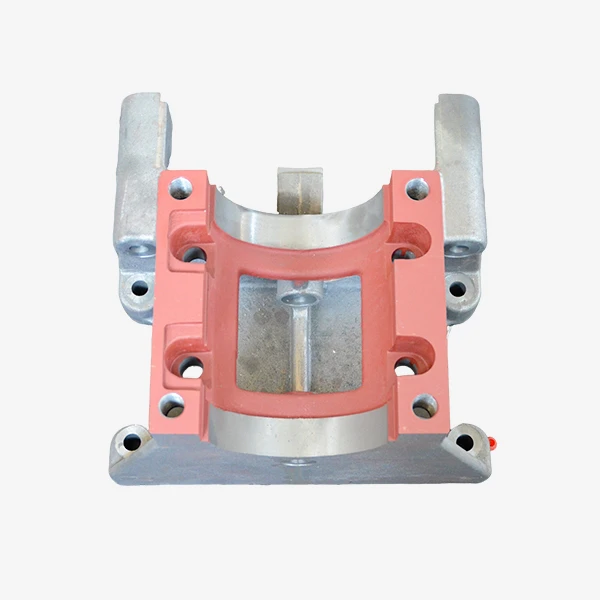

Warman Slurry Pump Base

The Slurry Pump Base is typically located at the bottom or as part of the supporting structure, fixed to the pump’s frame or base. It is usually connected to key components such as the motor, pump casing, and bearings.

The Slurry Pump Base is the foundation of the pump system, directly impacting the stability, service life, and operating efficiency of the pump. Therefore, special attention must be paid to support, alignment, and secure installation details during the setup process.

Installation and Maintenance of Slurry Pump Base

Specifications

The slurry pump base is generally not damaged and is not a wear part.

|

Base frame |

A |

B |

C |

D |

E |

R |

F |

G |

S |

T |

|

Allowable matching power (Kw) |

7.5 |

15 |

30 |

60 |

120 |

300 |

260 |

600 |

560 |

1200 |

|

Base weight (Kg) |

17 |

24 |

45 |

77.5 |

154 |

228 |

555 |

1006 |

546 |

1156 |

|

Shaft seal water volume (I/s) |

0.15 |

0.25 |

0.35 |

0.55 |

0.70 |

0.70 |

0.70 |

1.20 |

1.20 |

1.60 |

Product display

Slurry pump base part code

|

Frame Code |

AH Slurry Pump |

Materials |

|

B003M |

1.5/1B-AH, 2/1.5B-AH |

HT250, QT500 |

|

C003M |

3/2C-AH, 4/3C-AH |

HT250, QT500 |

|

D003M |

4/3D-AH, 6/4D-AH |

HT250, QT500 |

|

E003M |

6/4E-AH, 8/6E-AH |

HT250, QT500 |

|

R003M |

8/6R-AH |

HT250, QT500 |

|

FAM003M |

8/6F-AH, 10/8F-AH, 12/10F-AH |

HT250, QT500 |

|

ST003M |

10/8ST-AH, 12/10ST-AH, 14/12ST-AH |

HT250, QT500 |

|

TU003 |

16/14TU-AH, 18/16TU-AH, 20/18TU |

HT250, QT500 |

|

Frame Code |

HH Slurry Pump |

Materials |

|

C003M |

1.5/1C-HH |

HT250, QT500 |

|

D003M |

3/2D-HH |

HT250, QT500 |

|

E003M |

4/3E-HH |

HT250, QT500 |

|

F003M |

6/4F-HH |

HT250, QT500 |

|

Frame Code |

M Slurry Pump |

Materials |

|

E003M |

10/8E-M |

HT250, QT500 |

|

R003M |

10/8R-M |

HT250, QT500 |

|

Frame Code |

L Slurry Pump |

Materials |

|

A003M |

20A-L |

HT250, QT500 |

|

B003M |

50B-L |

HT250, QT500 |

|

C003M |

75C-L |

HT250, QT500 |

|

D003M |

100D-L |

HT250, QT500 |

|

E003M |

150E-L |

HT250, QT500 |

|

S003M |

300S-L |

HT250, QT500 |

|

Frame Code |

G(H) Gravel Pump |

Materials |

|

D003M |

6/4D-G |

HT250, QT500 |

|

E003M |

8/6E-G |

HT250, QT500 |

|

F003M |

10/8F-G |

HT250, QT500 |

|

S003M |

10/8S-G, 10/8S-GH |

HT250, QT500 |

|

G003M |

12/10G-G, 14/12G-G, 12/10G-GH |

HT250, QT500 |

|

TU003 |

16/14TU-GH |

HT250, QT500 |

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.