The Power Of The Froth Pump: Enhancing Efficiency In Industrial Processes

Are you looking to improve efficiency in your industrial processes? Look no further than the power of the froth pump. In this article, we explore how this technology can enhance productivity and streamline operations. Read on to discover how the froth pump can revolutionize your manufacturing processes.

- Understanding the Role of Froth Pumps in Industrial Processes

In industrial processes such as mining, wastewater treatment, and chemical processing, the role of froth pumps is crucial in maintaining efficiency and productivity. Froth pumps are specifically designed to handle frothy slurries, which are a common byproduct of these industrial processes. Understanding the unique capabilities and functions of froth pumps is essential in order to optimize their performance and ensure smooth operation.

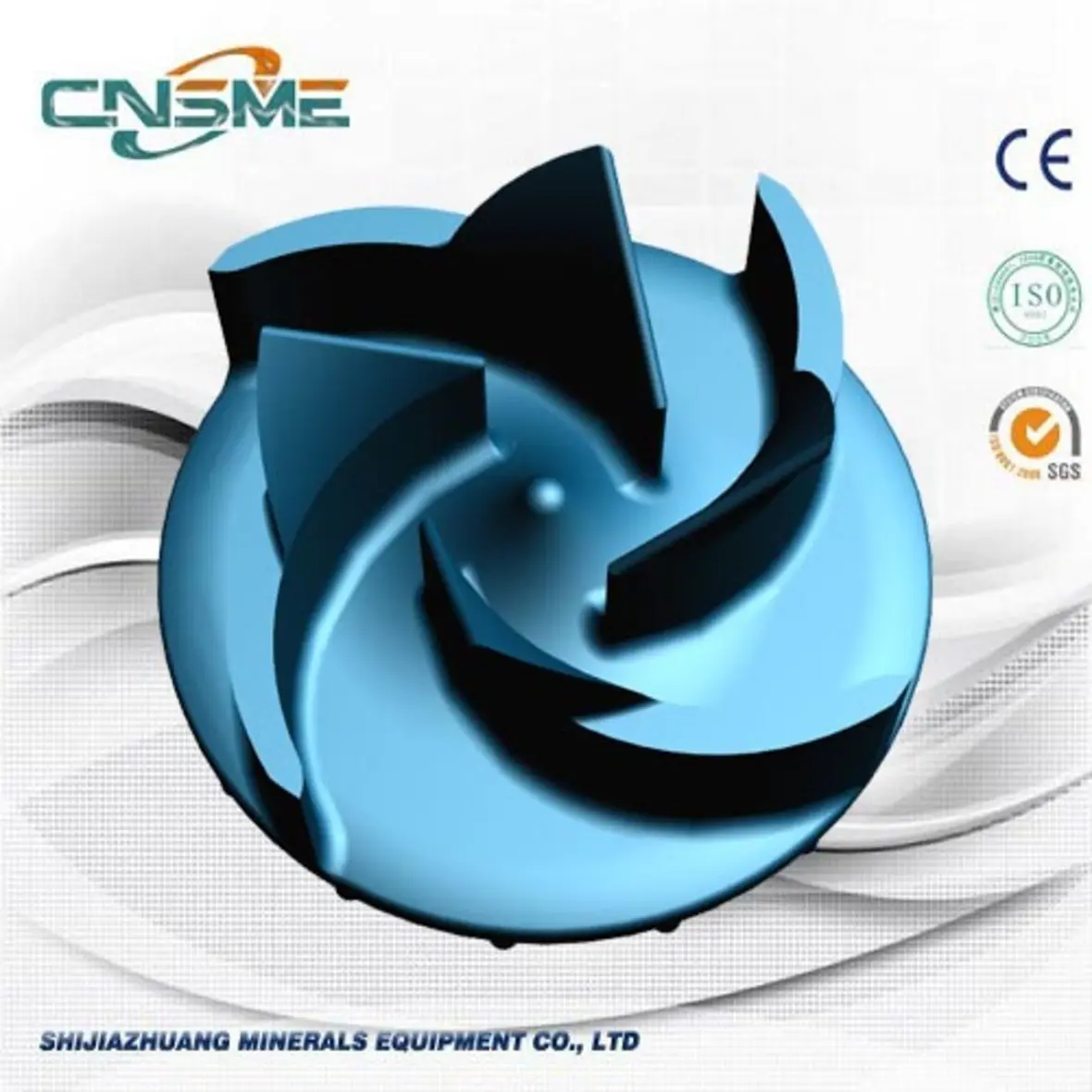

Froth pumps are specially designed to handle frothy slurries, which contain a high concentration of air bubbles. These air bubbles can significantly reduce the efficiency of conventional slurry pumps, as they can cause cavitation and air locking. Froth pumps, on the other hand, are equipped with features such as large impellers and specialized designs that allow them to effectively handle frothy slurries without experiencing these issues.

One of the key features of froth pumps is their ability to entrain air into the slurry, creating a frothy mixture that can be easily transported. This helps to improve the efficiency of the pumping process, as it reduces the amount of solid material that needs to be transported. Additionally, froth pumps are able to handle a wide range of froth densities, making them versatile and adaptable to different industrial processes.

Froth pumps play a vital role in froth flotation, a common process used in mining and mineral processing. During froth flotation, minerals are separated from gangue by creating a froth layer on top of the slurry. Froth pumps are used to transport this froth layer to the flotation cells, where the minerals are separated from the gangue. Without froth pumps, the froth layer would collapse, leading to decreased efficiency and poor separation outcomes.

In wastewater treatment plants, froth pumps are used to handle the frothy sludge that is produced during the treatment process. This frothy sludge contains a high concentration of suspended solids and air bubbles, making it difficult to transport using conventional pumps. Froth pumps are able to effectively handle this challenging material, ensuring that the wastewater treatment process runs smoothly and efficiently.

In chemical processing plants, froth pumps are used to handle frothy chemical slurries that are produced during various chemical reactions. These frothy slurries can be highly corrosive and abrasive, making them difficult to handle with conventional pumps. Froth pumps are able to withstand the harsh conditions of chemical processing plants, ensuring reliable and efficient operation.

Overall, froth pumps play a critical role in enhancing efficiency in industrial processes. By understanding the unique capabilities and functions of froth pumps, industries can optimize their performance and achieve higher levels of productivity. Whether in mining, wastewater treatment, or chemical processing, froth pumps are essential for handling frothy slurries and maintaining smooth operation.

- Benefits of Using Froth Pumps for Efficient Operations

Froth pumps play a crucial role in enhancing efficiency in industrial processes, making them an essential component for various applications. These specialized pumps are specifically designed to handle frothy slurries and high-viscosity fluids, providing numerous benefits that contribute to more effective operations. In this article, we will explore the advantages of using froth pumps in industrial settings and how they can help streamline processes and improve overall productivity.

One of the key benefits of utilizing froth pumps is their ability to efficiently handle frothy slurries. Froth, which is formed by the presence of air bubbles in the slurry, can be challenging to pump effectively with conventional pumps. Froth pumps are equipped with unique design features, such as large impellers and agitators, that allow them to effectively disperse and transport frothy slurries without clogging or cavitation. This capability helps to prevent downtime and maintenance issues, resulting in more reliable and continuous operation.

In addition to handling frothy slurries, froth pumps are also highly effective at pumping high-viscosity fluids. These pumps are specifically designed to accommodate dense and viscous materials, such as thickened tailings or concentrated chemicals, that may be difficult to pump with standard equipment. By using froth pumps, industrial processes can be optimized for increased efficiency and productivity, as these pumps are able to efficiently transfer high-viscosity fluids with minimal energy consumption.

Furthermore, froth pumps are known for their robust construction and durability, making them ideal for demanding industrial environments. These pumps are typically made from high-quality materials, such as hardened steel or abrasion-resistant alloys, that are able to withstand harsh operating conditions and abrasive materials. This durability not only extends the lifespan of the pump but also reduces the need for frequent replacements or repairs, ultimately lowering maintenance costs and enhancing operational efficiency.

Moreover, froth pumps offer versatile performance capabilities that can be tailored to specific process requirements. These pumps can be customized with various features, such as adjustable impeller sizes, multiple discharge options, and specialized coating materials, to optimize performance and efficiency for different applications. This versatility allows froth pumps to adapt to changing process conditions and ensure consistent and reliable operation in diverse industrial settings.

In conclusion, the power of froth pumps lies in their ability to enhance efficiency in industrial processes by effectively handling frothy slurries, high-viscosity fluids, and abrasive materials. By leveraging the unique capabilities of froth pumps, industries can optimize their operations, reduce downtime, and increase productivity. With their durable construction, versatile performance, and reliable operation, froth pumps have become indispensable tools for improving efficiency and achieving optimal performance in industrial processes.

- Factors to Consider When Selecting the Right Froth Pump

The Power of the Froth Pump: Enhancing Efficiency in Industrial Processes - Factors to Consider When Selecting the Right Froth Pump

In industrial processes where froth is a common byproduct, the use of a froth pump can significantly enhance efficiency and productivity. Froth pumps are specifically designed to handle frothy slurries, making them essential equipment in industries such as mining, pulp and paper, and wastewater treatment. When selecting the right froth pump for your application, there are several factors to consider to ensure optimal performance and maximum cost-effectiveness.

One of the most important factors to consider when choosing a froth pump is the type of froth being produced in your process. Different froths have varying levels of viscosity, gas content, and stability, which can affect the pump's performance. It is essential to choose a pump that is specifically designed to handle the type of froth you are dealing with to prevent clogging, cavitation, and other operational issues.

Additionally, the size and capacity of the froth pump must be matched to the requirements of your process. Oversized pumps can result in energy wastage and unnecessary wear and tear, while undersized pumps may not be able to handle the volume of froth effectively. It is crucial to carefully assess the flow rate, head pressure, and other operational parameters to select a pump that is the right fit for your specific application.

The material of construction is another critical consideration when selecting a froth pump. Frothy slurries can be highly abrasive and corrosive, so choosing a pump made from durable and resistant materials is essential for long term reliability and performance. Materials such as stainless steel, rubber, and high-chrome alloys are commonly used in froth pumps to withstand the harsh conditions of frothy applications.

Furthermore, the design and configuration of the froth pump can also impact its efficiency and effectiveness. Features such as air entrainment prevention, froth baffles, and special impeller designs can help improve pump performance and reduce maintenance requirements. It is important to work with a reputable pump manufacturer or supplier to ensure that the pump design is tailored to your specific needs and operating conditions.

In addition to the technical specifications of the froth pump, cost considerations are also crucial when making a selection. While upfront costs are important, it is essential to consider the overall lifecycle costs of the pump, including maintenance, repair, and energy consumption. Investing in a high-quality pump from a reliable manufacturer may result in lower long-term costs and improved operational efficiency.

Overall, selecting the right froth pump for your industrial process requires careful consideration of various factors, including froth type, capacity, material of construction, design, and cost. By choosing a pump that is tailored to your specific requirements and operating conditions, you can enhance efficiency, productivity, and overall performance in frothy applications. Working with experienced pump suppliers and manufacturers can help ensure that you make the best choice for your process and achieve optimal results.

- Maximizing Efficiency Through Proper Maintenance and Operation of Froth Pumps

In the industrial world, efficiency is key to success. From mining to food processing, reliable equipment is necessary to keep operations running smoothly. One often-overlooked but crucial piece of equipment in many industrial processes is the froth pump. Froth pumps are used to handle frothy slurries in industries such as mineral processing, paper production, and wastewater treatment. Maximizing efficiency through proper maintenance and operation of froth pumps can have a significant impact on overall productivity and cost-effectiveness.

Froth pumps are specifically designed to handle frothy slurries, which are mixtures of solid particles and air or gas bubbles. These pumps are essential in industries where froth is a common occurrence, as they are able to effectively transport these challenging materials. Froth pumps play a critical role in processes such as flotation, where valuable minerals are separated from gangue by utilizing the differences in surface properties of the particles. In these applications, froth pumps must be able to handle a high volume of froth while maintaining a stable flow and pressure.

Proper maintenance of froth pumps is essential to ensure optimal performance and longevity. Regular inspections should be conducted to check for wear and tear on pump components, such as impellers and liners. Any signs of damage should be addressed promptly to prevent further issues. In addition, froth pumps should be cleaned regularly to remove any buildup of froth or other debris that can impede performance. By keeping froth pumps well-maintained, operators can minimize downtime and avoid costly repairs.

In addition to maintenance, proper operation of froth pumps is crucial for maximizing efficiency. Operators should be trained on the correct use of froth pumps, including how to adjust the pump speed and impeller size to optimize performance for specific applications. Monitoring pump performance regularly can help identify potential issues before they escalate, allowing for timely intervention. By operating froth pumps at their optimal conditions, operators can ensure reliable and consistent performance while minimizing energy consumption.

Furthermore, selecting the right froth pump for the job is essential for enhancing efficiency in industrial processes. Factors such as the type of slurry being handled, flow rate, and pressure requirements must be taken into account when choosing a froth pump. Different pump designs, such as horizontal or vertical configurations, may be more suitable for certain applications. Consulting with pump manufacturers and experts can help ensure the selection of the most appropriate froth pump for the specific needs of the industry.

In conclusion, the power of the froth pump cannot be underestimated in industrial processes. By maximizing efficiency through proper maintenance and operation of froth pumps, industries can achieve higher productivity, reduced downtime, and cost savings. Investing in quality froth pumps and implementing best practices in maintenance and operation can lead to improved overall performance and competitiveness in the market. As technology continues to evolve, froth pumps will play an increasingly important role in enhancing efficiency and sustainability in industrial processes.

- Innovations in Froth Pump Technology for Enhanced Industrial Performance

In the ever-evolving landscape of industrial processes, the importance of efficient equipment cannot be overstated. One such crucial component is the froth pump, a device that plays a pivotal role in various industries, from mining to wastewater treatment. The subtitle of this article, “Innovations in Froth Pump Technology for Enhanced Industrial Performance,” speaks to the significant advancements being made in this field to improve efficiency and productivity.

The froth pump is specifically designed to handle frothy slurries, which are notoriously difficult to pump due to their high air content. Traditional centrifugal pumps often struggle with frothy fluids, leading to inefficiencies and increased maintenance costs. This is where froth pumps shine, as they are equipped with special features that enable them to effectively handle frothy slurries without clogging or losing performance.

One of the key innovations in froth pump technology is the incorporation of air separation mechanisms. By separating air from the slurry before it enters the pump, these devices are able to maintain a consistent flow and pressure, even when dealing with highly aerated fluids. This not only improves the overall efficiency of the pump but also minimizes wear and tear, leading to longer operational lifespans.

Another crucial aspect of froth pump technology is the use of advanced materials and design techniques. From abrasion-resistant liners to optimized impeller designs, manufacturers are constantly seeking ways to enhance the durability and performance of froth pumps. By utilizing cutting-edge materials such as rubber compounds and ceramic coatings, these pumps are able to withstand the harsh conditions often encountered in industrial processes.

Furthermore, advancements in motor technology have allowed froth pumps to operate more efficiently and quietly than ever before. By utilizing variable frequency drives and other energy-saving features, these pumps are able to adjust their speed and power consumption based on the specific demands of the application. This not only reduces energy costs but also contributes to a more sustainable and environmentally friendly operation.

In addition to technological innovations, the integration of digital monitoring and control systems has revolutionized the way froth pumps are managed. By utilizing real-time data analytics and predictive maintenance algorithms, operators are able to optimize pump performance, identify potential issues before they escalate, and minimize downtime. This proactive approach to maintenance not only improves overall efficiency but also reduces operational costs in the long run.

In conclusion, the froth pump is a critical component in enhancing efficiency and productivity in industrial processes. With continuous innovations in technology and design, these pumps are becoming more reliable, durable, and efficient than ever before. By embracing these advancements and leveraging the capabilities of modern froth pump technology, industries can achieve enhanced performance and profitability in their operations.

Conclusion

In conclusion, the froth pump has proven to be a valuable tool in enhancing efficiency in industrial processes. With over 20 years of experience in the industry, our company has witnessed firsthand the transformative power of this technology. By effectively managing froth and increasing productivity, businesses can streamline operations and maximize output. As we continue to innovate and improve upon existing technologies, the future looks bright for industries seeking to boost their efficiency and competitiveness. Embracing the power of the froth pump is just one step towards achieving success in the ever-evolving landscape of industrial processes.

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.