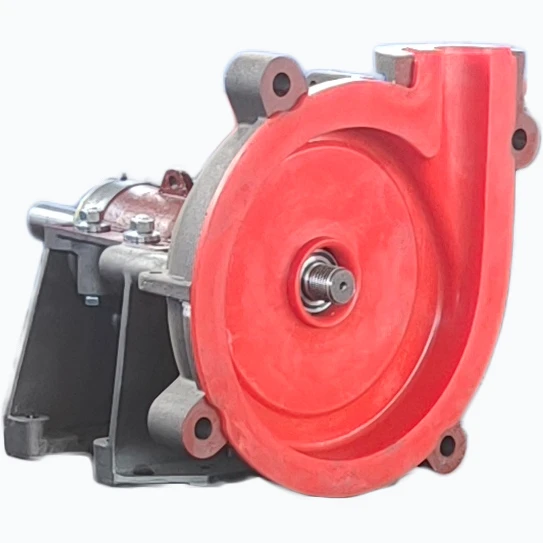

Slurry Pump Frame Plate, Cover Plate & Liners – Core Wet End Parts

A typical slurry pump wet-end assembly is made up of:

-

Frame Plate: The rear part of the pump casing that supports the bearing assembly and houses the liner. It withstands system pressure and provides structural strength.

-

Cover Plate: The front part of the pump casing that connects to the frame plate, sealing the pump chamber and allowing easy disassembly for inspection or maintenance.

-

Frame Plate Liner: A replaceable liner fitted inside the frame plate to protect it from abrasive slurry wear.

-

Cover Plate Liner: A matching liner fitted inside the cover plate to protect it from erosion and corrosion.

These liners are made from high-chrome alloy or natural rubber to meet various application requirements. The rugged casing combined with replaceable liners ensures excellent wear life, reduced maintenance downtime, and cost-effective operation.

Key Features:

✔️ High resistance to abrasion and impact

✔️ Replaceable liners for extended pump life

✔️ Easy maintenance and quick replacement

✔️ Compatible with Warman® and other standard slurry pumps

CNSME Pump’s high-quality casing and liners guarantee safe, stable, and efficient slurry transport in mining, mineral processing, dredging, and other heavy-duty industries.

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.