Labyrinth of Sump Pump Spare Parts

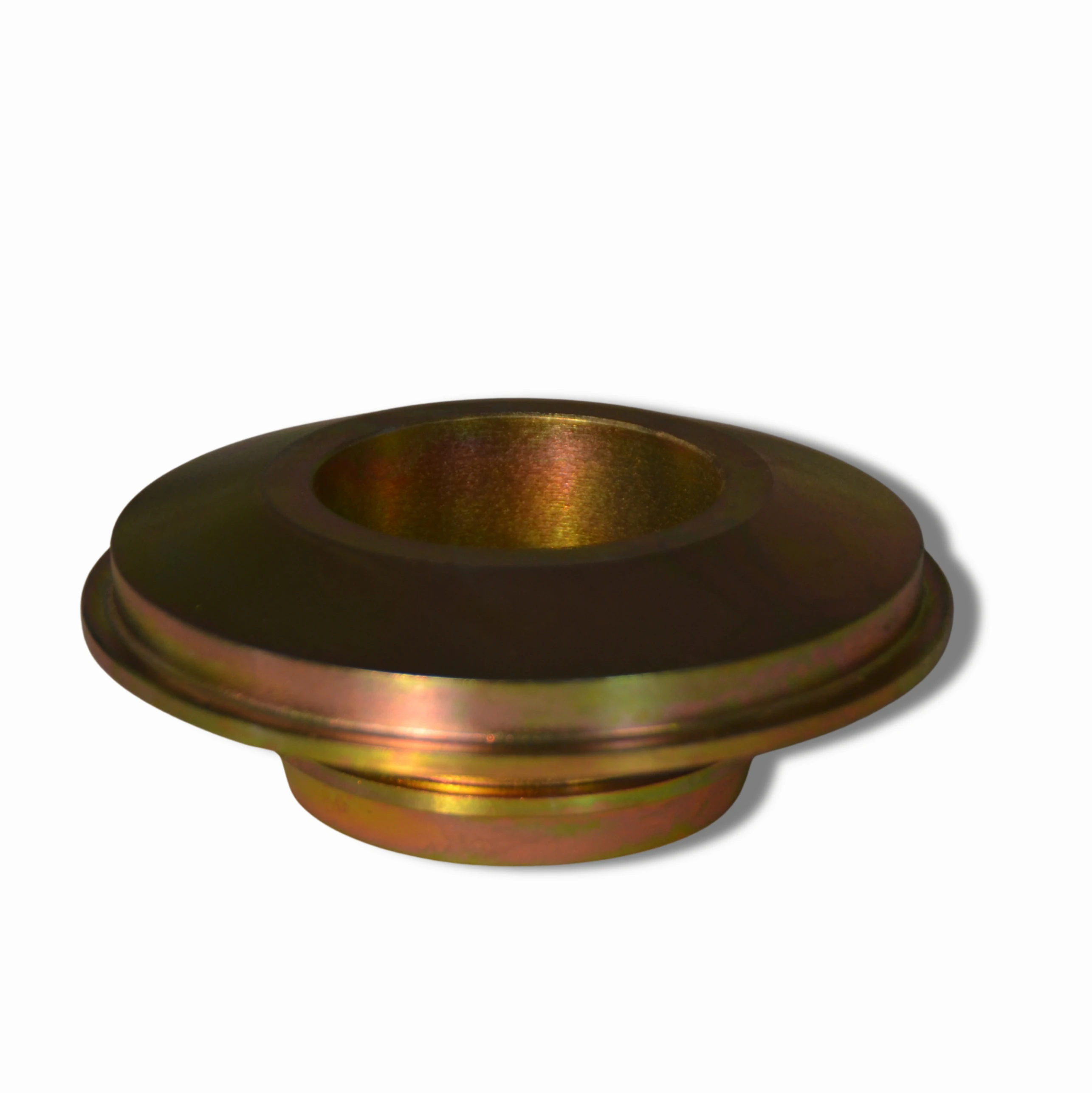

In a sump pump, the labyrinth is typically located in the shaft sealing section. Its primary function is to serve as a physical barrier, preventing internal liquids or slurry from leaking out of the pump while keeping external contaminants from entering the pump.

Labyrinth seals are widely used to enhance the operating efficiency of sump pumps, especially under conditions of high temperatures, strong corrosion, or high slurry concentrations. Their labyrinth-style design effectively reduces friction and wear, significantly extending the pump’s service life.

Product features:

No contact required, low friction wear

Simple structure, easy to install and replace

Wear and corrosion resistant, suitable for various working conditions

Improves the reliability and service life of bearing components

Applicable equipment:

Submersible slurry pumps (such as models 65QV-SP, 100RV-SP, 150SV-SP, etc.)

Labyrinth Installation Instructions

Installation Location: The base should be installed on a flat, solid surface to ensure the entire pump remains level during operation. If the base is unstable, it can affect the pump's performance and service life.

Fastening: During installation, the base must be bolted securely to the ground or support frame. Bolts should be tightened to the specified torque to prevent loosening.

Alignment: The pump shaft and motor shaft must be precisely aligned to ensure smooth operation and avoid unnecessary wear or abnormal vibration.

Vibration Isolation: In high-vibration environments, rubber pads or other vibration isolation devices can be used to minimize the impact of vibrations on other pump components.

Inspection and Maintenance: After installation, the base and connected components should be regularly inspected to ensure they are not loose or damaged, preventing any adverse effects on pump operation.

Main spare parts for SUMP pump

| PART NAME | BASIC NO. | 40PVSP | 65QVSP | 100RVSP | 150SVSP | 200SVSP | 250TVSP | 300TVSP |

| CASING | 092 | SP4092 | SP65092 | SP10092 | SP15092 | SP20092 | SP25092 | SP30092 |

| IMPELLER | 206 | SP4206 | SP65206 | SP10206 | SP15206 | SP20206 | SP25206 | SP30206 |

| FRAME PLATE LINER INSERT | 041 | SP4041 | SP65041 | SP10041 | SP15041 | SP20041 | SP25041 | SP30041 |

| SHAFT | 073 | PV4073 | QV65073 | RV10073 | SV15073 | SV20073 | TV25073 | TV30073 |

| DISCHARGE PIPE | 154 | PV4154 | QV65154 | RV10154 | SV15154 | SV20154 | TV25154 | TV30154 |

| MOUNTING PLATE | 019 | PV4019 | QV65019 | RV10019 | SV15019 | SV20019 | TV25019 | TV30019 |

| COLUMN | 102 | PV4102 | QV65102 | RV10102 | SV15102 | SV20102 | TV25102 | TV30102 |

| STRAINER | 116-1 | SP4116-1 | SP65116-1 | SP10116-1 | SP15116-1 | SP20116-1 | SP25116-1 | SP30116-1 |

| LOWER STRAINER | 116L | SP4116L | SP65116L | SP10116L | SP15116L | SP20116L | SP25116L | SP30116L |

| O-RING | 217 | PV217 | QV217 | RV217 | SV217 | SV217 | TV217 | TV217 |

| O-RING | 064 | PV064 | QV064 | RV064 | SV064 | SV064 | FSC064 | FSC064 |

| OIL SLINGER | 184 | PV184 | QV184-1 | RV184-1 | SV184-1 | SV184-1 | TV184-1 | TV184-1 |

| BEARING SEAL | 089 | PV089 | QV189 | RV089 | SV089 | SV089 | TV089 | TV089 |

| END COVER | 024 | PV024 | QV024 | RV024 | SV024 | SV024 | TV024 | TV024 |

| LOWER END COVER | 024L | PV024L | QV024L | RV024L-1 | SV024L-1 | SV024L-1 | TV024L-1 | TV024L-1 |

| DISCHARGE JOINT | 204 | SP4204 | SP65204 | SP10204 | SP20204 | SP20204 | SP25204 | SP25204 |

| CASING SEAL | 124/125 | SP4125 | D3125 | E4124 | F8124 | F8124 | SP25124 | SP25124 |

| LABYRINTH | 062 | PV062 | QV062 | RV062 | SV062 | SV062 | TV062 | TV062 |

| SHAFT SLEEVE EJECTOR | 077 | PV077 | QV077 | RV077 | SV077 | SV077 | TV077 | TV077 |

| BEARING SLEEVE | 008 | PV008 | QV008 | RV008 | SV008 | SV008 | TV008 | TV008 |

| BEARINGS | 009 | P009/P009D-1 | Q009/Q009D-1 | R009/R009D-1 | S009/S009D-1 | S009/S009D-1 | T009/T009D-1 | T009/T009D-1 |

| BEARING HOUSING | 004 | PV004 | QV004-1 | RV004-1 | SV004-1 | SV004-1 | TV004-1 | TV004-1 |

| BEARING ASSEMBLY | 005 | PV4005 | QV65005 | RV10005 | SV15005 | SV20005 | SV25005 | SV30005 |

Main spare parts for bearing assemblies

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.