Understanding The Efficiency And Benefits Of Vertical Slurry Pumps

Are you looking for a solution to increase efficiency and productivity in your industrial operations? Look no further - in this article, we delve into the world of vertical slurry pumps and the myriad benefits they offer. From improved performance to cost savings, understanding these pumps could revolutionize the way you approach your pumping needs. Join us as we explore the efficiency and benefits of vertical slurry pumps and discover how they can elevate your operations to new heights.

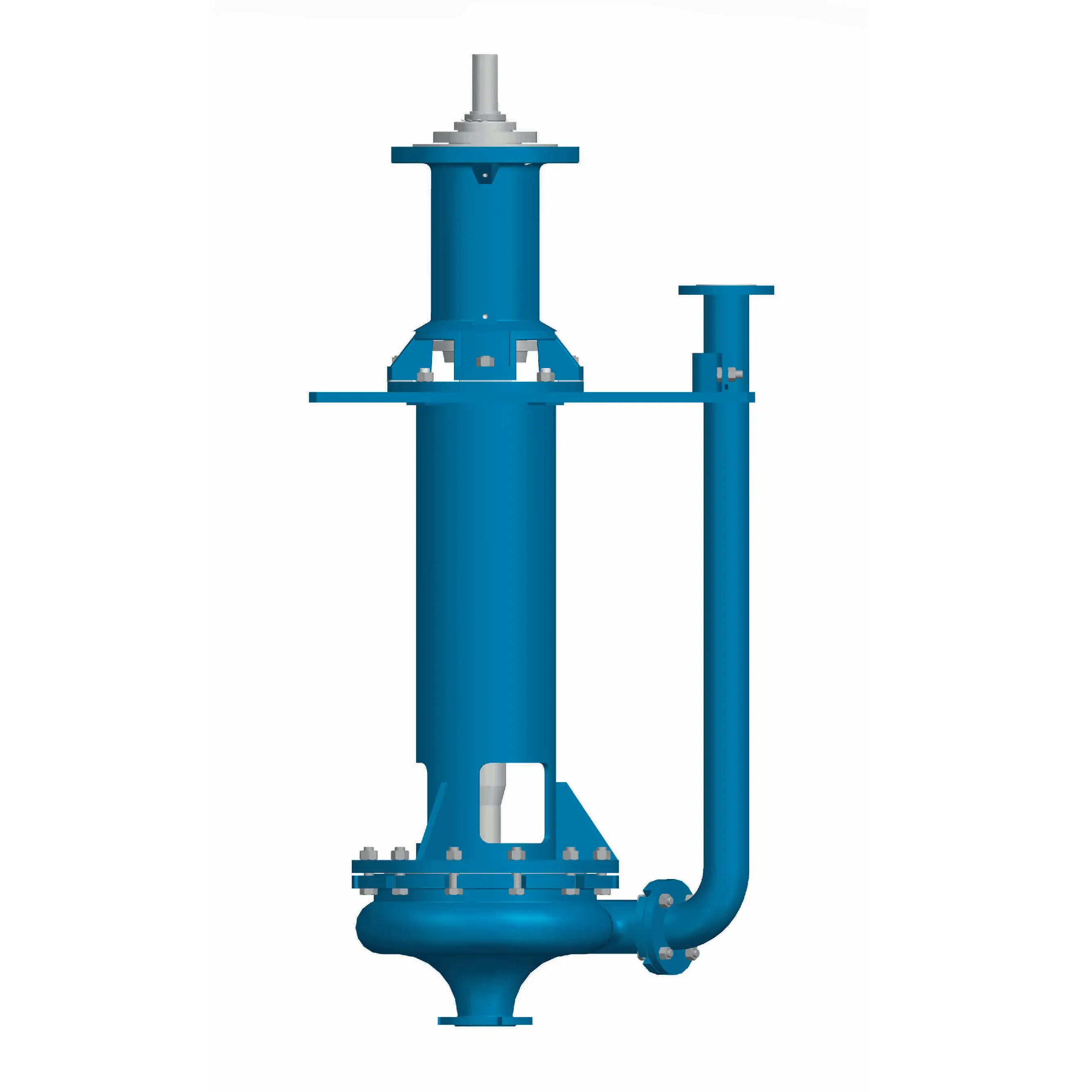

Overview of Vertical Slurry Pumps

Vertical slurry pumps are a type of pump that is specifically designed to handle abrasive and corrosive slurries. These pumps are typically used in industries such as mining, mineral processing, coal preparation, power generation, and chemical processing. The main advantage of vertical slurry pumps is their ability to efficiently transport slurries with high solid content without clogging or wearing down.

One of the key features of vertical slurry pumps is their vertical design, which allows them to be installed in tight spaces and provide a space-saving solution. These pumps are typically equipped with a vertical shaft which is submerged in the slurry, and the impellers are located at the bottom of the pump. This design allows for efficient pumping of the slurry without the risk of airlocks or cavitation.

Vertical slurry pumps are also known for their high efficiency and low maintenance requirements. These pumps are designed to handle abrasive and corrosive materials, which can cause wear and tear on traditional pumps. However, vertical slurry pumps are constructed with materials that are resistant to abrasion and corrosion, such as high-chrome alloys or rubber liners. This ensures that the pump is able to withstand the harsh conditions of slurry transport and require minimal maintenance over time.

Another benefit of vertical slurry pumps is their versatility. These pumps are capable of handling a wide range of slurries with varying concentrations and compositions. Whether it is a highly abrasive slurry from a mining operation or a corrosive slurry from a chemical processing plant, vertical slurry pumps are able to effectively pump the material without issues.

In addition to their efficiency and durability, vertical slurry pumps also offer energy savings. Due to their vertical design, these pumps require less power to operate compared to horizontal pumps. This can result in significant cost savings for industries that rely on slurry pumping for their operations.

Overall, vertical slurry pumps provide a reliable and efficient solution for industries that need to transport abrasive and corrosive slurries. With their vertical design, high efficiency, low maintenance requirements, and energy savings, these pumps are a valuable asset for any operation that deals with challenging slurry transport applications.

Advantages of Vertical Slurry Pumps over Horizontal Pumps

Vertical slurry pumps have gained widespread popularity in various industries over the years due to their numerous advantages over traditional horizontal pumps. These vertical pumps are specially designed to handle tough and abrasive slurries efficiently, making them the preferred choice for applications in mining, oil and gas, and wastewater treatment plants. In this article, we will delve into the efficiency and benefits of vertical slurry pumps in comparison to horizontal pumps.

One of the main advantages of vertical slurry pumps is their space-saving design. Unlike horizontal pumps that require a larger footprint for installation, vertical pumps can be installed in a smaller space, making them ideal for applications where space is limited. This space-saving feature also simplifies maintenance and servicing, as vertical pumps are easier to access and work on.

Vertical slurry pumps are also known for their superior efficiency in handling slurries with high solid content. The vertical design of these pumps allows for the solids to settle at the bottom of the pump, preventing them from clogging the impeller or causing unnecessary wear and tear. This results in reduced maintenance costs and downtime, as well as improved overall performance.

Furthermore, vertical slurry pumps are highly versatile and can be customized to meet specific application requirements. They can be made from a variety of materials, including high-chrome alloys and rubber, to ensure maximum durability and corrosion resistance. Additionally, vertical pumps can be equipped with various sealing options, such as packing seals or mechanical seals, to prevent leakage and ensure a reliable operation.

Another key advantage of vertical slurry pumps is their ability to handle high flow rates and pressures with ease. The vertical orientation of these pumps allows for a straight and direct flow path, minimizing energy loss and ensuring maximum efficiency. This makes vertical pumps ideal for applications that require high-performance and reliability, such as dewatering, slurry transfer, and tailings processing.

In conclusion, vertical slurry pumps offer numerous advantages over traditional horizontal pumps, including space-saving design, superior efficiency, versatility, and high performance. These pumps are a cost-effective solution for handling tough and abrasive slurries in various industries, making them an essential component in any pumping system. With their innovative design and advanced features, vertical slurry pumps continue to set the standard for reliability and efficiency in slurry handling applications.

Efficiency in Handling Abrasive and Corrosive Materials

In industries such as mining, wastewater treatment, and chemical processing, the handling of abrasive and corrosive materials is a common challenge. Traditional pump systems are often inefficient and prone to wear and tear when faced with these demanding applications. However, vertical slurry pumps have emerged as a reliable and efficient solution for transferring abrasive and corrosive materials with ease.

Vertical slurry pumps are specially designed to handle slurries and solids-laden fluids, making them ideal for applications where traditional pumps would struggle. The vertical design of these pumps allows for a space-saving installation and easy maintenance, making them a popular choice for various industrial settings.

One of the key benefits of vertical slurry pumps is their efficiency in handling abrasive materials. The robust construction of these pumps, including high-quality materials such as hardened iron and corrosion-resistant alloys, ensures that they can withstand the wear and tear caused by abrasive particles. This durability not only prolongs the pump's lifespan but also reduces maintenance costs and downtime.

In addition to their ability to handle abrasive materials, vertical slurry pumps are also highly effective in handling corrosive fluids. The corrosion-resistant materials used in their construction make them suitable for applications where acids, alkalis, and other corrosive substances are present. This ensures that the pump remains operational and reliable even in harsh chemical environments.

Furthermore, vertical slurry pumps offer significant advantages in terms of performance and efficiency. Their innovative design features, such as high-efficiency impellers and adjustable suction liners, allow for optimal flow rates and minimal energy consumption. This results in lower operating costs and improved overall performance, making vertical slurry pumps a cost-effective solution for industries dealing with abrasive and corrosive materials.

Overall, the efficiency and benefits of vertical slurry pumps make them a valuable asset in industries where the handling of abrasive and corrosive materials is a constant challenge. Their durable construction, corrosion-resistant materials, and high-performance capabilities make them a reliable and cost-effective solution for transferring slurries and solids-laden fluids with ease. By investing in vertical slurry pumps, industries can improve their operational efficiency, reduce maintenance costs, and enhance overall productivity in dealing with challenging applications.

Applications and Industries Benefiting from Vertical Slurry Pumps

Vertical slurry pumps are powerful tools that play a crucial role in a wide range of applications and industries. These pumps are specially designed to handle abrasive and corrosive slurries, making them ideal for challenging environments where traditional pumps may fail. In this article, we will explore the efficiency and benefits of vertical slurry pumps, as well as the applications and industries that can benefit from their use.

One of the key advantages of vertical slurry pumps is their efficiency in handling tough materials. The design of these pumps allows them to efficiently transport slurries with high solids content, such as mining tailings, cement slurries, and industrial waste. Their robust construction and heavy-duty materials ensure long-lasting performance in demanding conditions, minimizing downtime and maintenance costs.

Vertical slurry pumps are commonly used in industries such as mining, oil and gas, wastewater treatment, and construction. In the mining industry, these pumps are essential for dewatering underground mines and processing plants, as well as transporting tailings and slurry to storage facilities. Oil and gas companies rely on vertical slurry pumps for slurry injection, drilling mud transfer, and pipeline boosting. In wastewater treatment plants, these pumps are used to handle sludge, grit, and slurry from sewage and industrial processes.

The versatility of vertical slurry pumps also makes them suitable for a wide range of applications. They can be used for pumping abrasive materials, such as sand, gravel, and coal, as well as corrosive chemicals and acids. Their vertical design allows for easy installation in confined spaces, such as sumps and tanks, making them ideal for retrofitting existing systems or integrating into new installations.

In addition to their efficiency and versatility, vertical slurry pumps offer several other benefits to industries and applications. These pumps are designed to operate at high speeds and pressures, ensuring efficient performance even in the most challenging conditions. They also have low maintenance requirements, thanks to their sturdy construction and advanced sealing systems, reducing operating costs and downtime.

Furthermore, vertical slurry pumps are environmentally friendly, as they minimize the risk of spills and leaks due to their robust design and reliable performance. They also help industries comply with regulations and sustainability guidelines by safely handling abrasive and corrosive materials without environmental harm.

Overall, vertical slurry pumps are indispensable tools for industries and applications that require efficient and reliable handling of abrasive and corrosive slurries. Their efficiency, versatility, and benefits make them a valuable asset for mining, oil and gas, wastewater treatment, and construction sectors. By investing in high-quality vertical slurry pumps, industries can improve their operations, reduce costs, and contribute to a more sustainable future.

Factors to Consider When Selecting the Right Vertical Slurry Pump for Your Needs

Vertical slurry pumps are essential in many industries where handling abrasive and corrosive materials is a common occurrence. Choosing the right pump for your specific needs is crucial to ensure efficient and reliable operation. Factors such as the pump's efficiency, size, material construction, and maintenance requirements all play a role in determining which pump is best suited for your application.

Efficiency is a key factor to consider when selecting a vertical slurry pump. A pump that operates efficiently will save energy and reduce operational costs. Look for pumps that are designed with advanced engineering features, such as high-performance impellers and casings, to ensure optimal efficiency. Additionally, consider the pump's flow rate and head pressure capabilities to ensure it can handle the demands of your specific application.

Another important consideration when selecting a vertical slurry pump is the size of the pump. Choosing a pump that is too small may result in inadequate performance, while a pump that is too large can lead to unnecessary energy consumption. It is important to carefully assess the size and capacity requirements of your system to determine the appropriate pump size for your needs.

Material construction is also a crucial factor to consider when selecting a vertical slurry pump. The pump should be constructed with durable materials that can withstand the abrasive and corrosive nature of the materials being pumped. Look for pumps that are made from high-quality materials such as stainless steel or high-chrome alloys to ensure long-lasting performance and reliability.

Maintenance requirements should also be taken into account when selecting a vertical slurry pump. Look for pumps that are designed with easy access to key components for routine maintenance and inspection. Pumps that are equipped with features such as replaceable wear parts and self-lubricating bearings can help to reduce downtime and maintenance costs.

In conclusion, selecting the right vertical slurry pump for your needs requires careful consideration of factors such as efficiency, size, material construction, and maintenance requirements. By taking the time to assess these factors, you can ensure that you choose a pump that will provide reliable performance and long-lasting durability for your specific application.

Conclusion

As a company with 20 years of experience in the industry, we have seen firsthand the efficiency and benefits of vertical slurry pumps. From their ability to handle abrasive materials to their space-saving design, these pumps offer a wide range of advantages for various industries. By understanding the unique capabilities of vertical slurry pumps, companies can improve their operations, reduce maintenance costs, and increase overall productivity. Investing in quality vertical slurry pumps is not just a wise choice for businesses, but a strategic decision that can lead to long-term success. With our expertise and experience, we are confident that we can help you find the right vertical slurry pump for your needs. Contact us today to learn more about the efficiency and benefits of vertical slurry pumps and how they can enhance your operations.

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.