The Power Of Horizontal Centrifugal Slurry Pumps: Enhancing Efficiency In Industrial Applications

Are you looking to enhance efficiency in your industrial applications? Look no further than the power of horizontal centrifugal slurry pumps. In this article, we will explore how these pumps can revolutionize your operations and maximize productivity. Stay tuned to discover how this technology can take your industrial processes to the next level.

- Understanding the Functionality of Horizontal Centrifugal Slurry Pumps

Industrial applications require reliable and efficient machinery to handle the demanding tasks of moving abrasive and corrosive materials. One essential component in this process is the horizontal centrifugal slurry pump. In this article, we will delve into the functionality of these powerful pumps and how they enhance efficiency in various industrial applications.

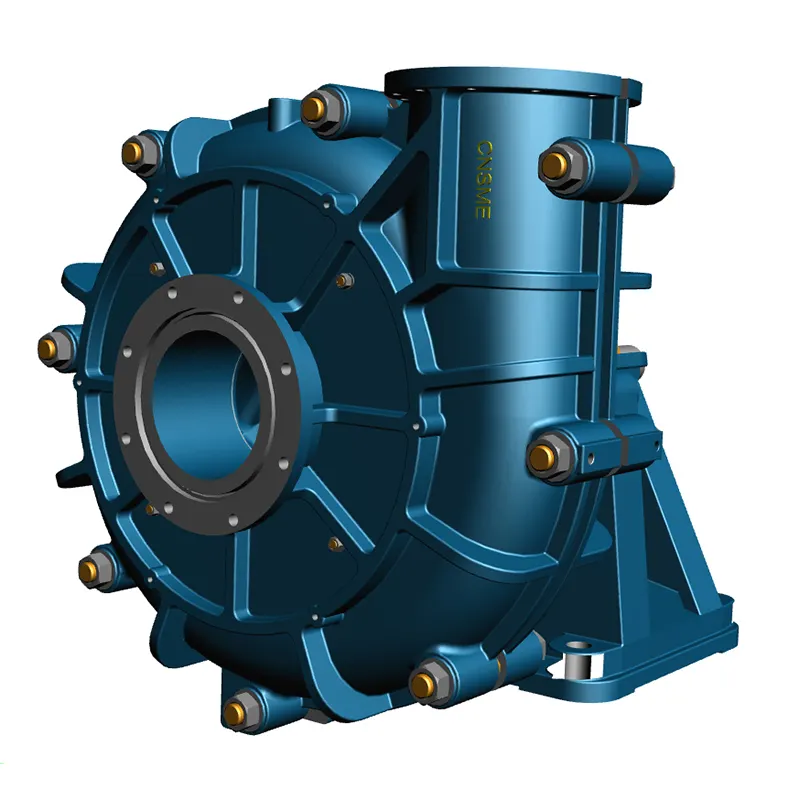

A horizontal centrifugal slurry pump is a type of pump that is specifically designed to handle slurries – a mixture of solid particles and liquid. These pumps are commonly used in industries such as mining, construction, and chemical processing, where the transportation of abrasive and corrosive materials is a common occurrence.

The key feature of a horizontal centrifugal slurry pump is its ability to move slurry with high efficiency and minimal energy consumption. The pump works by converting mechanical energy from a motor into kinetic energy, which is used to move the slurry through the system. The horizontal orientation of the pump allows for easy installation and maintenance, making it a popular choice in industrial settings.

One of the main benefits of using horizontal centrifugal slurry pumps is their robust design and ability to handle a wide range of materials. These pumps are equipped with wear-resistant materials such as high-chrome alloys and rubber linings, which can withstand the harsh conditions of handling abrasive slurries. The design of the pump also minimizes the risk of clogging and impeller damage, ensuring continuous and reliable operation.

In addition to their durability, horizontal centrifugal slurry pumps offer superior performance in terms of efficiency and cost-effectiveness. These pumps are designed to operate at high speeds, allowing for quick and efficient transfer of materials. The compact design of the pump also reduces energy consumption, leading to lower operational costs and increased productivity.

Furthermore, horizontal centrifugal slurry pumps are versatile and can be customized to suit specific industrial applications. With options such as different impeller designs, materials, and sizes, these pumps can be tailored to meet the unique requirements of various industries. Whether it is mining, chemical processing, or wastewater treatment, horizontal centrifugal slurry pumps provide a reliable and efficient solution for handling abrasive materials.

In conclusion, horizontal centrifugal slurry pumps play a crucial role in enhancing efficiency and productivity in industrial applications. Their robust design, superior performance, and versatility make them an ideal choice for handling abrasive and corrosive materials. By understanding the functionality of these powerful pumps, industries can optimize their processes and achieve greater success in their operations.

- Key Benefits of Using Horizontal Centrifugal Slurry Pumps in Industrial Processes

Horizontal centrifugal slurry pumps have become a vital component in numerous industrial processes due to their ability to enhance efficiency and productivity. These pumps play a crucial role in transporting abrasive and high-density slurries in various industries such as mining, construction, and wastewater treatment. In this article, we will explore the key benefits of using horizontal centrifugal slurry pumps in industrial applications.

One of the primary advantages of horizontal centrifugal slurry pumps is their ability to handle a wide range of slurries with varying viscosities and solid concentrations. These pumps are specifically designed to handle abrasive and corrosive materials, making them ideal for challenging industrial environments. The robust construction of horizontal centrifugal slurry pumps ensures long-lasting performance and minimal maintenance requirements, reducing downtime and overall operational costs.

Furthermore, horizontal centrifugal slurry pumps are known for their high efficiency and energy-saving capabilities. The design of these pumps allows for smooth and continuous flow of slurries, minimizing energy consumption and maximizing productivity. With their high efficiency, horizontal centrifugal slurry pumps can significantly reduce operating costs and improve overall process performance in industrial applications.

Another key benefit of using horizontal centrifugal slurry pumps is their versatility and flexibility in application. These pumps can be easily integrated into existing systems or customized to meet specific requirements, making them suitable for a wide range of industrial processes. Whether it is transporting slurry in mining operations or handling wastewater in treatment plants, horizontal centrifugal slurry pumps are a reliable and versatile solution for various industrial applications.

In addition to their performance and efficiency benefits, horizontal centrifugal slurry pumps are also known for their durability and reliability. The sturdy construction and advanced technology used in these pumps ensure long-term performance even in the most demanding industrial conditions. This reliability factor is crucial in industries where continuous operation is essential for maintaining productivity and meeting production targets.

Overall, horizontal centrifugal slurry pumps have revolutionized industrial processes by providing a reliable, efficient, and cost-effective solution for handling abrasive and high-density slurries. With their ability to handle a wide range of materials, high efficiency, and durability, horizontal centrifugal slurry pumps have become an indispensable tool in various industries. By incorporating these pumps into industrial processes, companies can enhance efficiency, minimize downtime, and improve overall productivity.

- Improving Efficiency and Productivity with Horizontal Centrifugal Slurry Pumps

Horizontal centrifugal slurry pumps have revolutionized industrial applications by significantly improving efficiency and productivity. These powerful pumps are designed to handle abrasive and high-density slurries in a wide range of industries, including mining, oil and gas, wastewater treatment, and chemical processing.

One of the key benefits of using horizontal centrifugal slurry pumps is their ability to operate at high speeds, which allows for faster and more efficient material handling. Unlike traditional pumps that may struggle with abrasive materials, these pumps are specifically engineered to handle tough slurries with ease. This makes them ideal for applications where a high level of performance is required.

In addition to their impressive performance capabilities, horizontal centrifugal slurry pumps are also known for their reliability and durability. With their robust construction and heavy-duty materials, these pumps are designed to withstand the harsh conditions often found in industrial settings. This means less downtime and maintenance for businesses, leading to increased productivity and cost savings in the long run.

Another key advantage of using horizontal centrifugal slurry pumps is their versatility. These pumps can be customized to meet the specific needs of a wide range of industries, making them suitable for a variety of applications. Whether pumping corrosive chemicals or handling abrasive materials, these pumps can be tailored to deliver optimal performance in any situation.

Overall, the power of horizontal centrifugal slurry pumps lies in their ability to enhance efficiency in industrial applications. By improving material handling processes and reducing downtime, these pumps enable businesses to operate more effectively and achieve greater productivity. With their reliability, durability, and versatility, horizontal centrifugal slurry pumps are a valuable asset for any business looking to streamline operations and maximize performance.

- Case Studies: Real-world Applications of Horizontal Centrifugal Slurry Pumps

Horizontal centrifugal slurry pumps have been a game-changer in industrial applications, revolutionizing the way materials are handled and processed in various industries. These pumps have proven to be essential in enhancing efficiency, reducing downtime, and ultimately improving overall productivity. In this article, we will delve into the real-world applications of horizontal centrifugal slurry pumps through case studies that showcase their effectiveness and versatility.

One of the key benefits of horizontal centrifugal slurry pumps is their ability to handle highly abrasive and corrosive materials. This makes them ideal for industries such as mining, mineral processing, and chemical processing, where transferring and processing of such materials is a common challenge.

In a case study from the mining industry, a large copper mine was facing issues with their traditional pumps failing prematurely due to the abrasive nature of the slurry being transported. They switched to horizontal centrifugal slurry pumps and saw a significant improvement in pump longevity and efficiency. These pumps were able to handle the abrasive slurry with ease, reducing maintenance costs and increasing overall operational efficiency.

Another key advantage of horizontal centrifugal slurry pumps is their ability to handle high concentrations of solids. This makes them suitable for applications such as dredging, wastewater treatment, and aggregate processing, where large volumes of solids need to be transported.

In a case study from the wastewater treatment industry, a municipal treatment plant was struggling to effectively pump sludge with high solids content. They switched to horizontal centrifugal slurry pumps and noticed a dramatic improvement in pumping efficiency. The pumps were able to handle the high solids concentration without clogging or excessive wear, leading to smoother operations and reduced downtime.

Furthermore, horizontal centrifugal slurry pumps are known for their energy efficiency, offering substantial cost savings in terms of energy consumption. This makes them a preferred choice for industries looking to reduce their operating costs and environmental footprint.

In a case study from the food and beverage industry, a beverage processing plant was using traditional pumps that were consuming a significant amount of energy to transport viscous liquids. By switching to horizontal centrifugal slurry pumps, they were able to reduce their energy consumption by 30%, resulting in substantial cost savings and a more sustainable operation.

Overall, horizontal centrifugal slurry pumps have proven to be a powerful tool in enhancing efficiency and productivity in a wide range of industrial applications. Their ability to handle abrasive and corrosive materials, high solids concentrations, and their energy-efficient design make them a valuable asset for industries looking to optimize their processes and maximize their output. These case studies have provided real-world examples of the impact that horizontal centrifugal slurry pumps can have, showcasing their versatility and effectiveness in various industries.

- Future Trends and Innovations in Horizontal Centrifugal Slurry Pump Technology

Horizontal centrifugal slurry pumps have become an essential component in various industrial applications, offering enhanced efficiency and performance. With futuristic trends and innovations continuously shaping the technology behind these pumps, industries are experiencing a significant shift towards improved productivity and reliability.

One of the key trends in horizontal centrifugal slurry pump technology is the development of advanced materials for increased durability and corrosion resistance. Manufacturers are constantly researching and implementing new materials such as hardened steel, ceramic, and specialized coatings to extend the lifespan of these pumps in harsh operating environments. This not only reduces maintenance costs but also ensures uninterrupted operation in critical industrial processes.

Furthermore, the integration of digital monitoring and control systems is revolutionizing the way horizontal centrifugal slurry pumps are operated and maintained. By collecting real-time data on pump performance, temperature, and vibration levels, operators can proactively identify potential issues before they escalate into costly breakdowns. This predictive maintenance approach not only minimizes downtime but also optimizes energy consumption, leading to significant cost savings for industries.

Another innovation in horizontal centrifugal slurry pump technology is the use of computational fluid dynamics (CFD) simulations for designing more efficient pump impellers and casings. By analyzing fluid flow patterns and optimizing the pump geometry, manufacturers can achieve higher pump efficiencies and reduced energy consumption. This not only benefits industries by lowering operating costs but also contributes to environmental sustainability through reduced energy wastage.

In addition, the incorporation of adjustable speed drives (ASDs) in horizontal centrifugal slurry pumps allows for precise control of pump speed and flow rates according to changing process demands. This results in improved process stability and reduced wear and tear on pump components, ultimately extending the pump's operational lifespan. Industries can expect increased flexibility and versatility in their operations, thanks to the intelligent automation capabilities of these pumps.

Overall, the advancements in horizontal centrifugal slurry pump technology are driving a paradigm shift in industrial applications, empowering industries to achieve new levels of efficiency and reliability. With ongoing research and development in this field, we can expect further innovations that will continue to enhance the performance and capabilities of these essential equipment. The future holds great promise for horizontal centrifugal slurry pumps as they play a crucial role in powering industrial processes towards greater success.

Conclusion

In conclusion, the power of horizontal centrifugal slurry pumps cannot be underestimated when it comes to enhancing efficiency in industrial applications. With 20 years of experience in the industry, our company understands the importance of choosing the right pump for the job. By investing in high-quality pumps that are designed to handle the rigorous demands of industrial settings, businesses can optimize their operations and increase productivity. The reliability and performance of horizontal centrifugal slurry pumps make them a valuable asset for any industrial facility looking to streamline their processes and maximize efficiency. Trust in our expertise and experience to help you find the perfect pump solution for your specific needs.

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.