The Importance Of Properly Maintaining Your Slurry Pump Seal

A slurry pump is a crucial component of many industrial processes, and the seal plays a vital role in its functionality. In this article, we will explore the importance of properly maintaining your slurry pump seal and the potential consequences of neglecting this essential task. From preventing leaks to extending the lifespan of your equipment, discover how regular maintenance can significantly impact the performance and efficiency of your slurry pump.

- Understanding the Role of the Slurry Pump Seal

Slurry pumps are essential equipment in various industries such as mining, construction, and wastewater treatment. These pumps are designed to handle abrasive and corrosive slurries, making them prone to wear and tear. One of the critical components of a slurry pump is the seal, which plays a crucial role in preventing leakage and maintaining the efficiency of the pump.

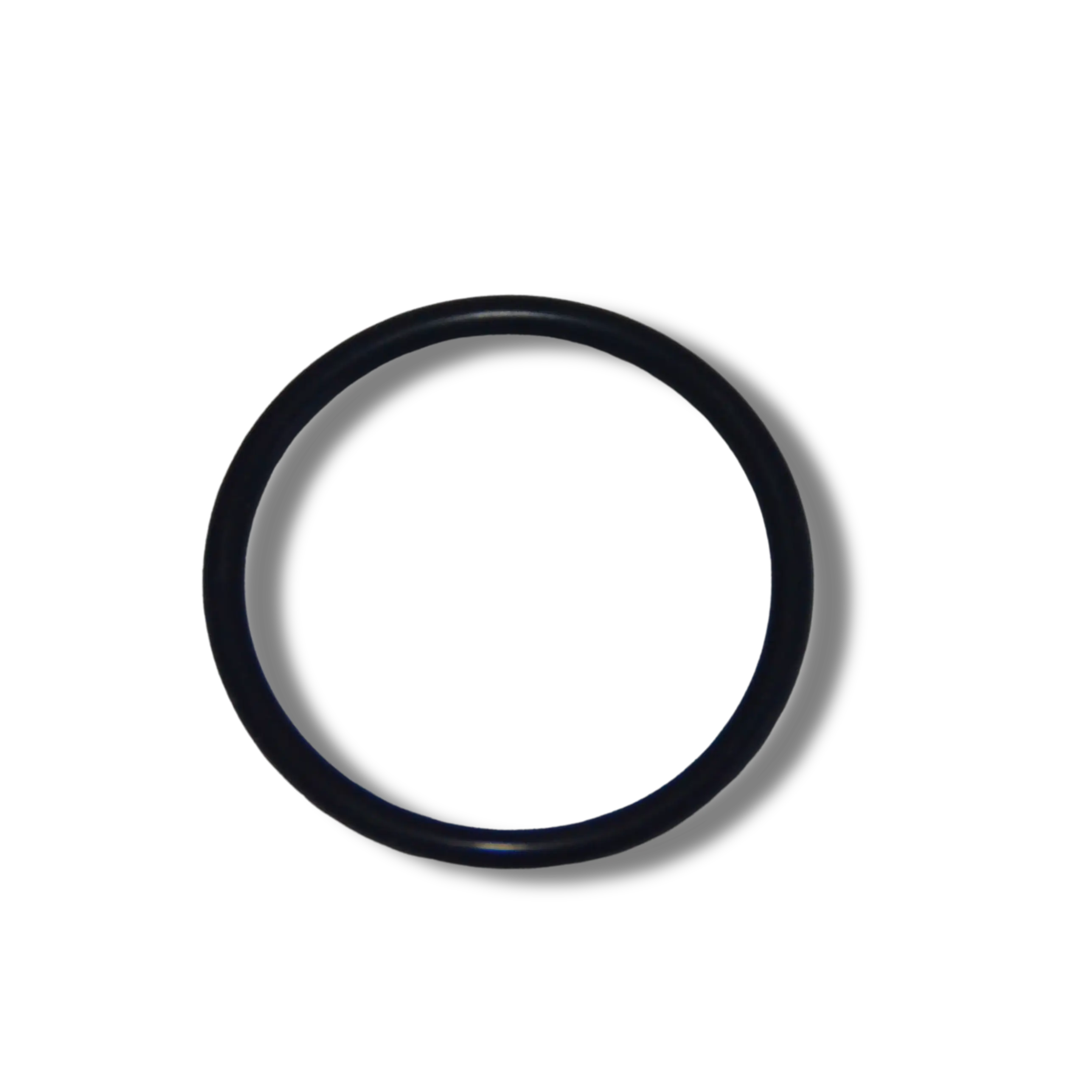

The slurry pump seal is a mechanical device that prevents slurry from leaking out of the pump. There are several types of seals used in slurry pumps, including packing seals, mechanical seals, and lip seals. Each type of seal has its advantages and disadvantages, but all serve the same purpose of keeping the slurry contained within the pump.

Proper maintenance of the slurry pump seal is essential to ensure the efficient operation of the pump. A faulty seal can lead to leakage, which not only reduces the pump's efficiency but can also cause environmental and safety hazards. Regular inspections and maintenance are necessary to detect any signs of wear or damage to the seal.

One of the common issues with slurry pump seals is abrasion and corrosion. The abrasive nature of the slurry can cause wear on the seal, leading to premature failure. Corrosive slurry can also damage the seal material, compromising its effectiveness. It is crucial to choose the right type of seal material that can withstand the harsh conditions of the slurry being pumped.

Another factor that can affect the performance of the slurry pump seal is the pressure and temperature of the slurry. High-pressure and high-temperature applications require seals that are capable of handling these extreme conditions. Improper selection of the seal can result in seal failure, leading to costly downtime and repairs.

In addition to selecting the right seal material, proper installation and alignment of the seal are crucial for ensuring its effectiveness. A misaligned or improperly installed seal can result in leakages and reduced pump performance. Regular monitoring of the seal's condition and making necessary adjustments can help prolong the life of the seal and prevent unexpected failures.

In conclusion, the slurry pump seal plays a vital role in maintaining the efficiency and reliability of a slurry pump. Proper maintenance, selection of the right seal material, and regular inspections are essential for ensuring the seal's effectiveness. By understanding the importance of the slurry pump seal and taking proactive measures to maintain it, businesses can avoid costly downtime and repairs, ensuring smooth operation of their slurry pumps.

- Consequences of Neglecting Seal Maintenance

Slurry pumps are essential equipment in many industries, including mining, construction, and wastewater treatment. They are used to transport abrasive and corrosive slurries, making proper maintenance crucial for their efficient operation. One critical component of a slurry pump is the seal, which prevents leakage and contamination of the pumped material. Neglecting seal maintenance can have severe consequences, leading to increased downtime, higher repair costs, and decreased overall pump performance.

One of the primary reasons for seal failure is improper installation. If the seal is not installed correctly, it can lead to leaks and premature wear, reducing the pump's efficiency. Regular inspections and maintenance are necessary to ensure that the seal is properly installed and functioning as intended. This includes checking for wear and tear, lubricating the seal, and replacing any damaged parts.

Another issue that can arise from neglecting seal maintenance is increased energy consumption. A worn or damaged seal can cause the pump to work harder to maintain the desired flow rate, leading to higher energy costs. In addition, leaks from a faulty seal can result in the loss of valuable pumped material, further adding to operating expenses. By maintaining the seal properly, pump operators can significantly reduce energy consumption and improve overall pump efficiency.

Inadequate seal maintenance can also lead to contamination of the pumped material. If the seal fails, foreign substances can enter the pump, causing damage to internal components and reducing the pump's lifespan. Contaminated slurry can also pose safety risks to personnel and harm the environment. Regular maintenance of the seal is essential to prevent any contamination and ensure the pump operates safely and efficiently.

Furthermore, neglecting seal maintenance can result in costly repairs and unplanned downtime. A damaged seal can cause extensive damage to other pump components, leading to expensive repairs and extended downtime. In industries where continuous operation is crucial, such as mining and wastewater treatment, any unplanned downtime can have significant financial consequences. Properly maintaining the seal can help avoid these costly repairs and keep the pump running smoothly.

In conclusion, the seal is a critical component of a slurry pump, and neglecting its maintenance can have severe consequences. By properly installing, inspecting, and maintaining the seal, pump operators can prevent leaks, reduce energy consumption, avoid contamination, and minimize the risk of costly repairs. Investing in regular seal maintenance is essential for ensuring the efficient operation of a slurry pump and extending its lifespan.

- Tips for Properly Maintaining Your Slurry Pump Seal

A slurry pump seal is an essential component of any slurry pump system, as it plays a crucial role in preventing leaks and maintaining the efficiency of the pump. Proper maintenance of the slurry pump seal is vital to ensure that the pump continues to operate at its optimal performance. In this article, we will discuss some important tips for properly maintaining your slurry pump seal.

One of the most important aspects of maintaining a slurry pump seal is ensuring that it is properly installed. Each slurry pump seal is designed to work with specific pump models, so it is important to follow the manufacturer's instructions when installing the seal. This will help to ensure that the seal fits properly and is able to effectively prevent leaks.

Regular inspection of the slurry pump seal is also essential for proper maintenance. It is important to check for any signs of wear or damage, as these can lead to leaks and decrease the efficiency of the pump. If any wear or damage is found, the seal should be replaced promptly to prevent further issues.

In addition to regular inspections, it is also important to clean the slurry pump seal regularly. Over time, dirt, debris, and other contaminants can build up on the seal, which can interfere with its ability to function properly. Cleaning the seal with a mild detergent and water can help to remove these contaminants and ensure that the seal remains in good condition.

Proper lubrication is another key factor in maintaining a slurry pump seal. The seal should be properly lubricated to ensure that it functions smoothly and effectively. It is important to use the appropriate type of lubricant for the seal, as using the wrong type can cause damage and reduce the lifespan of the seal.

Regular servicing of the slurry pump system is also important for maintaining the seal. This includes checking the pump for any leaks, as well as ensuring that all components are functioning properly. If any issues are detected during servicing, they should be addressed promptly to prevent further damage.

In conclusion, proper maintenance of the slurry pump seal is crucial for ensuring the efficient operation of a slurry pump system. By following the tips outlined in this article, you can help to prevent leaks, prolong the lifespan of the seal, and ensure that your pump continues to operate at its optimal performance. Remember to keep up with regular inspections, cleaning, lubrication, and servicing to maintain your slurry pump seal in good condition.

- Benefits of Regular Seal Inspections and Repairs

Slurry pump seals play a vital role in the efficient operation of slurry pumps in various industries, including mining, wastewater treatment, and construction. Regular inspections and repairs of these seals are crucial to ensuring the longevity and performance of the pumps. In this article, we will discuss the benefits of regular seal inspections and repairs for maintaining slurry pumps in optimal condition.

One of the most significant advantages of regular seal inspections is the early detection of potential issues. By conducting regular checks on the seals, operators can identify any signs of wear, damage, or leakage before they escalate into larger problems that can result in costly repairs or downtimes. This proactive approach to maintenance helps to prevent unexpected breakdowns and ensures continuous operation of the slurry pumps.

Furthermore, regular seal inspections can help to improve the overall efficiency of the slurry pump system. A properly functioning seal creates a tight barrier between the moving parts of the pump, preventing leakage and reducing energy consumption. By maintaining the seals in good condition, operators can maximize the pump's performance and minimize energy wastage, ultimately leading to cost savings and a more sustainable operation.

In addition to improving efficiency, regular seal inspections and repairs contribute to the safety of the workplace. Leaking seals can pose serious hazards to workers, as the abrasive nature of slurry can cause damage to skin and equipment. By keeping the seals in good condition, operators can create a secure working environment and reduce the risk of accidents and injuries.

Another important benefit of regular seal maintenance is the extension of the slurry pump's lifespan. Seals that are properly inspected and repaired on a consistent basis are less likely to fail prematurely, increasing the longevity of the pump and reducing the frequency of replacements. This not only saves on costs but also minimizes downtime and ensures uninterrupted operation.

Overall, the importance of properly maintaining slurry pump seals cannot be understated. Regular inspections and repairs offer numerous benefits, including early detection of issues, improved efficiency, enhanced safety, and extended lifespan of the pumps. By investing time and resources in the maintenance of these critical components, operators can ensure the reliable performance of their slurry pump systems and maximize their operational efficiency.

- Investing in Quality Parts for Long-Term Performance

Slurry pumps are crucial components in many industries, such as mining, construction, and wastewater treatment. They are used to transfer a mixture of water and solid particles, known as slurry, from one place to another. One of the key components of a slurry pump is the seal, which plays a vital role in preventing leaks and ensuring the pump operates efficiently. In this article, we will discuss the importance of properly maintaining your slurry pump seal, specifically investing in quality parts for long-term performance.

Slurry pump seals are designed to prevent slurry from leaking out of the pump and causing damage to the surrounding equipment. A well-maintained seal can significantly extend the life of the pump and reduce maintenance costs. By investing in quality parts for your slurry pump seal, you can ensure that it performs optimally for years to come.

One of the main reasons why investing in quality parts for your slurry pump seal is important is the harsh operating conditions that slurry pumps are subjected to. The abrasive nature of slurry can cause wear and tear on the seal, leading to leaks and decreased performance. By using high-quality materials for the seal, such as rubber or ceramic, you can prevent premature failure and ensure that the pump operates smoothly.

Another reason why investing in quality parts for your slurry pump seal is crucial is the importance of preventing downtime. In industries where slurry pumps are essential for daily operations, any downtime can result in significant financial losses. By using durable, long-lasting seals, you can minimize the risk of unexpected breakdowns and keep your operations running smoothly.

Additionally, investing in quality parts for your slurry pump seal can improve overall pump efficiency. A properly sealed pump will have less leakage, which means that more of the slurry is being transferred to its intended destination. This can result in cost savings for the operation, as less energy is wasted on pumping excess slurry.

When it comes to maintaining your slurry pump seal, there are several key steps that should be taken. Regular inspection of the seal for signs of wear and tear is essential, as well as replacing any damaged parts as needed. Proper lubrication and alignment of the seal are also important factors in ensuring its longevity and performance.

In conclusion, the importance of properly maintaining your slurry pump seal cannot be overstated. By investing in quality parts for long-term performance, you can prevent leaks, reduce downtime, and improve overall pump efficiency. Taking the time to properly care for your slurry pump seal will not only save you money in the long run but also ensure that your operations run smoothly and efficiently.

Conclusion

In conclusion, it is evident that the proper maintenance of your slurry pump seal is crucial for ensuring the optimal performance and longevity of your equipment. By following the tips and guidelines outlined in this article, you can prevent costly breakdowns and downtime, ultimately saving your company time and money. As a company with 20 years of experience in the industry, we understand the importance of regular maintenance and are committed to providing our customers with reliable and efficient solutions for their slurry pump seal needs. Thank you for choosing us as your trusted partner in maintaining the integrity of your equipment.

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.