Efficiently Transfer Foam With A Vertical Froth Pump

Are you looking for a more efficient way to transfer foam in your industrial processes? Look no further than the vertical froth pump. In this article, we will delve into the benefits of using a vertical froth pump for foam transfer, and how it can streamline your operations. Read on to discover how this innovative pump can improve your productivity and efficiency.

- Understanding the Role of a Vertical Froth Pump in Foam Transfer

Foam transfer is a crucial process in various industries, such as mining, mineral processing, and wastewater treatment. One of the key components used in foam transfer is a vertical froth pump. These pumps play a critical role in transferring foam efficiently and effectively. In this article, we will delve into the significance of vertical froth pumps in foam transfer and how they work to ensure smooth operations.

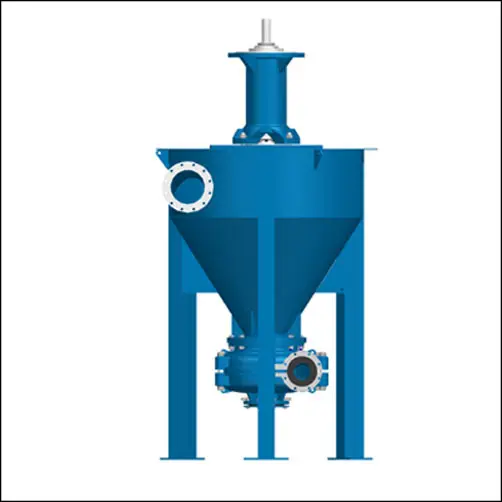

A vertical froth pump is specifically designed to handle frothy slurries and slurries with high viscosity. Unlike traditional horizontal pumps, vertical froth pumps are equipped with a unique design that allows them to handle froth and aerated slurries without clogging or losing efficiency. This makes them ideal for applications where foam transfer is required.

One of the key features of a vertical froth pump is its ability to prevent air lock and cavitation. Air lock occurs when air bubbles get trapped in the pump, causing a loss of efficiency and potential damage to the pump. Cavitation, on the other hand, happens when the pressure inside the pump drops, leading to the formation of vapor bubbles that can implode and cause wear and tear on pump components. Vertical froth pumps are designed to prevent these issues by effectively handling frothy slurries and maintaining a consistent flow.

In foam transfer applications, vertical froth pumps are used to transfer foam from one location to another with minimal loss of foam volume. The pump draws in the foam slurry from the bottom of the tank and discharges it from the top, ensuring that the foam remains intact throughout the transfer process. This helps maintain the quality of the foam and prevents any potential contamination or degradation.

Additionally, vertical froth pumps are designed to handle abrasive materials and corrosive chemicals commonly found in foam transfer applications. The pump components are made from durable materials that can withstand the harsh conditions and ensure long-lasting performance. This makes vertical froth pumps a reliable and cost-effective solution for foam transfer processes.

In conclusion, vertical froth pumps play a crucial role in foam transfer by efficiently handling frothy slurries and preventing air lock and cavitation. Their unique design and robust construction make them an ideal choice for industries that require reliable and efficient foam transfer operations. By understanding the role of a vertical froth pump in foam transfer, industries can improve their process efficiency and productivity.

- Benefits of Using a Vertical Froth Pump for Efficient Foam Transfer

Foam transfer is a critical process in various industries including mining, mineral processing, and sewage treatment. The efficient transfer of foam is essential to ensure the smooth operation of these industries. One effective way to transfer foam is by using a vertical froth pump. In this article, we will explore the benefits of using a vertical froth pump for efficient foam transfer.

A vertical froth pump is specifically designed to handle slurries with high froth content. This type of pump is equipped with a special air-liquid mixing mechanism that effectively breaks down the foam and allows for the transfer of the slurry without any loss of efficiency. The vertical design of the pump allows for easier installation and operation, making it an ideal choice for applications where space is limited.

One of the key benefits of using a vertical froth pump is its ability to handle high froth content. Froth is a common problem in industries where air is introduced into the slurry, such as in flotation cells. Traditional pumps struggle to handle frothy slurries, leading to inefficiencies and reduced productivity. A vertical froth pump, on the other hand, is specifically designed to handle froth and can effectively transfer the slurry without any foam build-up.

Another benefit of using a vertical froth pump is its energy efficiency. Traditional pumps require more power to handle frothy slurries, leading to increased energy consumption and operating costs. In contrast, a vertical froth pump is designed to operate efficiently even with high froth content, resulting in lower operating costs and reduced energy consumption.

The vertical design of the pump also offers additional benefits in terms of maintenance and reliability. Vertical froth pumps are easier to access and maintain, reducing downtime and maintenance costs. The vertical orientation of the pump also helps to prevent blockages and clogging, ensuring a reliable and continuous operation.

In conclusion, the use of a vertical froth pump offers several benefits for efficient foam transfer in various industries. From handling high froth content to energy efficiency and ease of maintenance, vertical froth pumps are an ideal choice for applications where foam transfer is a common challenge. By investing in a vertical froth pump, industries can improve productivity, reduce operating costs, and ensure a smooth and efficient foam transfer process.

- Factors to Consider for Optimal Performance of a Vertical Froth Pump

Efficiently Transfer Foam with a Vertical Froth Pump - Factors to Consider for Optimal Performance

A vertical froth pump is a crucial piece of equipment used in industries such as mining, mineral processing, and wastewater treatment to efficiently transfer foam. This type of pump is specifically designed to handle frothy slurries and is known for its ability to transport materials with a high percentage of air or gas. However, in order to ensure optimal performance of a vertical froth pump, there are several key factors that need to be considered.

One of the most important factors to consider when using a vertical froth pump is the design of the pump itself. This type of pump is typically equipped with a specially designed impeller that is able to effectively handle frothy materials. The impeller should be carefully selected based on the specific characteristics of the material being pumped, including the viscosity, density, and size of the particles. Additionally, the pump should be properly sized to ensure that it is able to handle the required flow rate and pressure.

Another important factor to consider is the installation and maintenance of the pump. Proper installation is essential to ensure that the pump operates efficiently and safely. The pump should be placed in a location that allows for easy access for maintenance and repairs. Regular maintenance is also crucial to ensure that the pump continues to operate at optimal performance. This includes regularly inspecting and replacing worn parts, checking for leaks, and monitoring the performance of the pump.

In addition to the design and maintenance of the pump, the operating conditions also play a key role in the performance of a vertical froth pump. Factors such as the temperature, pressure, and flow rate of the material being pumped can all affect the efficiency of the pump. It is important to carefully monitor these operating conditions and make adjustments as needed to ensure that the pump is able to operate at its full capacity.

Furthermore, the type of material being pumped can also impact the performance of a vertical froth pump. Different materials have varying characteristics that can affect the operation of the pump. For example, materials with high viscosity can be more difficult to pump and may require a larger pump with a more powerful motor. It is important to carefully consider the type of material being pumped when selecting a vertical froth pump and to make sure that the pump is appropriate for the specific application.

In conclusion, there are several key factors to consider when using a vertical froth pump to efficiently transfer foam. By carefully considering the design of the pump, proper installation and maintenance, operating conditions, and the type of material being pumped, it is possible to ensure optimal performance of the pump. With the right attention to detail and proper maintenance, a vertical froth pump can be an invaluable asset in a wide range of industrial applications.

- Comparing Vertical Froth Pumps to Other Foam Transfer Methods

Foam transfer is a crucial process in various industries such as mining, chemical processing, and wastewater treatment. Efficiently transferring foam is essential to maintain the productivity and effectiveness of these operations. One common method of transferring foam is through the use of vertical froth pumps. These pumps are specifically designed to handle foamy substances and have been proven to be effective in comparison to other foam transfer methods.

Vertical froth pumps are specially designed to handle frothy liquids, which contain a high volume of air or gas bubbles. These pumps are equipped with unique features that make them ideal for transferring foam efficiently. One of the key advantages of vertical froth pumps is their ability to handle highly aerated liquids without clogging or losing efficiency. This is achieved through the pump's design, which includes a froth cone and a tank to separate the foam from the liquid, allowing for smooth and continuous transfer.

In comparison to other foam transfer methods such as horizontal pumps or air lift pumps, vertical froth pumps offer several advantages. Horizontal pumps are not as efficient in handling foam due to their design, which can lead to clogging and reduced performance. Air lift pumps, on the other hand, are limited in their capacity and are not as effective in transferring foam over long distances. Vertical froth pumps, with their specialized design, are able to overcome these limitations and provide a reliable solution for transferring foam.

One of the key benefits of using vertical froth pumps is their versatility. These pumps can handle a wide range of foamy liquids, including those with high viscosity or abrasive properties. This makes them suitable for various applications, from mining and mineral processing to chemical processing and wastewater treatment. Additionally, vertical froth pumps are highly efficient, allowing for cost-effective foam transfer and reducing downtime due to clogging or maintenance issues.

Another advantage of vertical froth pumps is their durability and reliability. These pumps are constructed with high-quality materials that can withstand the harsh conditions often encountered in industrial environments. This ensures that the pump can operate efficiently over an extended period without the need for frequent repairs or replacements. Additionally, vertical froth pumps are designed for easy maintenance, allowing for quick and convenient servicing to minimize downtime.

In conclusion, vertical froth pumps are a highly efficient and reliable solution for transferring foam in various industrial applications. With their specialized design and ability to handle highly aerated liquids, these pumps offer significant advantages over other foam transfer methods. Their versatility, durability, and ease of maintenance make them a valuable investment for industries looking to improve their foam transfer processes. By choosing vertical froth pumps, companies can ensure smooth and continuous foam transfer, leading to increased productivity and operational efficiency.

- Tips for Maximizing Efficiency in Foam Transfer with a Vertical Froth Pump

Foam transfer is a crucial process in various industries, including mining, mineral processing, and wastewater treatment. To ensure optimal efficiency in this process, it is essential to use the right equipment, such as a vertical froth pump. In this article, we will discuss some tips for maximizing efficiency in foam transfer with a vertical froth pump.

First and foremost, it is important to understand the unique design and capabilities of a vertical froth pump. Unlike traditional horizontal pumps, vertical froth pumps are specifically designed to handle frothy slurries and improve air handling capabilities. This makes them ideal for applications where air is present in the slurry, such as when transferring foam.

One key tip for maximizing efficiency with a vertical froth pump is to properly size and select the pump for your specific application. Consider factors such as the size and viscosity of the foam, the distance of the transfer, and the flow rate required. Choosing the right pump size will ensure optimal performance and minimize energy consumption.

Another important tip is to maintain the pump regularly to ensure smooth operation. This includes checking for any signs of wear and tear, adjusting the impeller clearance, and monitoring the pump performance over time. Regular maintenance will help prevent costly downtime and ensure the longevity of the pump.

In addition, it is important to consider the installation and placement of the vertical froth pump. Proper installation, including correct alignment and support, will help reduce vibration and noise, and ensure efficient operation. Additionally, placing the pump at the optimal height and angle will help prevent air entrapment and improve suction performance.

Furthermore, optimizing the piping system and layout can also improve efficiency in foam transfer with a vertical froth pump. Ensure that the piping is properly sized, with minimal bends and obstructions, to reduce friction loss and improve flow rates. Properly designed piping systems can also help reduce air pockets and improve the overall performance of the pump.

Lastly, consider using additional accessories and features to maximize efficiency with a vertical froth pump. These may include features such as adjustable impeller clearances, anti-cavitation devices, and variable speed drives. These features can help improve pump performance, reduce energy consumption, and enhance overall efficiency in foam transfer.

In conclusion, maximizing efficiency in foam transfer with a vertical froth pump requires careful consideration of pump selection, maintenance, installation, piping layout, and additional features. By following these tips and utilizing the capabilities of a vertical froth pump, industries can improve their foam transfer processes, reduce costs, and enhance overall productivity.

Conclusion

In conclusion, the use of a vertical froth pump has proven to be a highly efficient method for transferring foam in industrial applications. With our 20 years of experience in the industry, we have seen firsthand the benefits of incorporating this technology into our operations. By utilizing a vertical froth pump, companies can increase productivity, reduce energy consumption, and improve overall performance. It is clear that this innovative solution is a game-changer for the foam transfer process, and we are excited to continue implementing this technology to drive success in our business.

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.