Mastering The Vertical Slurry Pump: A Comprehensive Guide For Efficiency And Performance

Are you looking to elevate the efficiency and performance of your vertical slurry pump? Look no further - our comprehensive guide is here to help you master the art of vertical slurry pumping. Whether you are a seasoned professional or just getting started in this field, our expert tips and insights will equip you with the knowledge and skills to optimize your pump's performance. Discover the key strategies to boost efficiency and maximize output, and take your pumping operations to the next level.

- Understanding the Basics of Vertical Slurry Pumps

Vertical slurry pumps are essential in a wide range of industries, from mining to wastewater treatment. Understanding the basics of these pumps is crucial for optimizing efficiency and performance. In this comprehensive guide, we will delve into all aspects of vertical slurry pumps, from their design and operation to maintenance and troubleshooting.

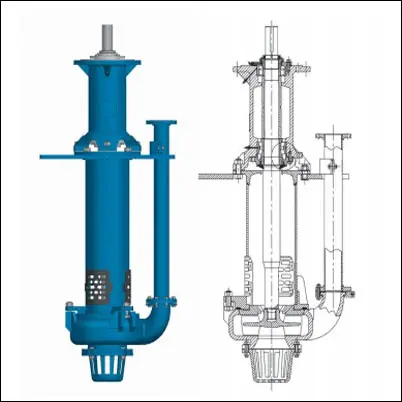

At the heart of a vertical slurry pump is its vertical orientation, with the impeller submerged in the slurry. This design allows for efficient pumping of abrasive and high-density slurries without the risk of clogging. The pump shaft is typically supported by bearings at the top and bottom, providing stability and preventing vibration during operation.

One of the key components of a vertical slurry pump is the impeller. The impeller plays a crucial role in creating the necessary centrifugal force to transport the slurry. It is important to select the right impeller size and design based on the specific characteristics of the slurry being pumped, such as particle size and concentration.

Another important aspect to consider when using vertical slurry pumps is the type of wear-resistant materials used in their construction. Hard-wearing materials such as high-chrome alloys or rubber are often employed to ensure longevity and minimize maintenance costs. Proper selection of materials can also prevent premature wear and tear, prolonging the pump's lifespan.

In terms of operation, vertical slurry pumps require proper installation and regular maintenance to ensure optimal performance. It is essential to follow manufacturer guidelines for installation, including proper alignment and tensioning of the pump shaft. Regular inspection of the pump components, such as the impeller and bearings, is also crucial to prevent unexpected downtime.

When it comes to troubleshooting vertical slurry pumps, common issues such as cavitation, overheating, and vibration should be addressed promptly. Cavitation occurs when air bubbles form in the slurry, leading to decreased pump efficiency and potential damage. To prevent cavitation, ensure the pump is properly primed and that the suction line is free from obstructions.

Furthermore, overheating can occur if the pump is operating beyond its rated capacity or if there is insufficient cooling. Monitoring the temperature of the pump and adjusting the operating conditions as needed can help prevent overheating. Vibration, on the other hand, can be a sign of misalignment or worn bearings, which should be corrected to prevent further damage.

In conclusion, mastering the basics of vertical slurry pumps is essential for achieving efficiency and performance in various industrial applications. By understanding the design, operation, maintenance, and troubleshooting of these pumps, users can ensure smooth and reliable operation for years to come. Vertical slurry pumps are a critical component in many industries, and proper care and attention to detail can make all the difference in their performance.

- Selecting the Right Vertical Slurry Pump for Your Needs

Vertical slurry pumps are essential equipment in various industries such as mining, construction, and wastewater treatment. These pumps play a crucial role in transporting solid particles and liquids efficiently and effectively. However, selecting the right vertical slurry pump for your specific needs can be a daunting task. In this comprehensive guide, we will delve into the intricacies of vertical slurry pumps, outlining key factors to consider when choosing the perfect pump for your operations.

1. Understanding the Basics of Vertical Slurry Pumps

Vertical slurry pumps are designed to handle abrasive and corrosive slurries with high solid content. They are typically used in applications where traditional pumps are not suitable due to their robust construction and efficient performance. These pumps are equipped with a vertical shaft and impeller that work together to move slurry from one location to another.

2. Factors to Consider When Selecting a Vertical Slurry Pump

- Flow Rate: The flow rate of a vertical slurry pump is crucial in determining its efficiency. It is essential to choose a pump that can handle the required flow rate without compromising performance.

- Head: The head of a pump refers to the vertical distance that the pump can lift the slurry. It is important to consider the head capacity of the pump to ensure it can meet the height requirements of your application.

- Solids Handling Capacity: Different vertical slurry pumps are designed to handle varying amounts of solid content in the slurry. It is essential to choose a pump with the appropriate solids handling capacity to avoid clogging and other issues.

- Material Compatibility: The material of construction of the pump is vital in determining its compatibility with the slurry being transported. It is crucial to select a pump made from materials that can withstand the corrosive and abrasive nature of the slurry.

3. Types of Vertical Slurry Pumps

There are several types of vertical slurry pumps available in the market, each catering to specific applications. These include:

- Submersible Vertical Slurry Pumps: These pumps are submerged in the slurry and are ideal for applications where space is limited.

- Cantilever Vertical Slurry Pumps: These pumps feature a single shaft design and are suitable for applications with low flow rates and high solid content.

- Sump Vertical Slurry Pumps: These pumps are installed in a sump and are used for dewatering and other applications requiring continuous pumping.

4. Maintenance and Troubleshooting

Proper maintenance of vertical slurry pumps is essential to ensure optimal performance and longevity. Regular inspection, cleaning, and lubrication of the pump components are necessary to prevent breakdowns and costly repairs. Additionally, monitoring the pump for signs of wear and tear, such as increased noise or vibration, can help identify potential issues before they escalate.

In conclusion, selecting the right vertical slurry pump for your specific needs requires careful consideration of various factors, including flow rate, head capacity, solids handling capacity, and material compatibility. By understanding the basics of vertical slurry pumps and choosing the appropriate type for your application, you can improve efficiency and performance in your operations. Remember, proper maintenance and troubleshooting are essential to ensure the longevity and reliability of your vertical slurry pump.

- Key Components and Maintenance Tips for Vertical Slurry Pumps

Vertical slurry pumps are essential equipment for many industries, including mining, construction, and wastewater treatment. These pumps are specifically designed to handle abrasive and corrosive slurries, making them ideal for applications where traditional pumps would quickly wear out. In this comprehensive guide, we will explore the key components of vertical slurry pumps and provide maintenance tips to ensure maximum efficiency and performance.

One of the key components of a vertical slurry pump is the impeller. The impeller is responsible for creating the centrifugal force necessary to move the slurry through the pump and into the discharge pipe. It is important to regularly inspect the impeller for wear and tear, as a damaged impeller can decrease the pump's efficiency and performance. Additionally, adjusting the impeller clearance can help optimize the pump's performance and reduce energy consumption.

Another important component of a vertical slurry pump is the casing. The casing houses the impeller and other internal components, providing protection from the abrasive slurry. Regularly inspecting the casing for cracks or leaks is essential to prevent slurry from leaking out of the pump and causing damage to the surrounding equipment. Additionally, ensuring proper alignment of the casing and impeller can help prevent vibration and prolong the pump's lifespan.

The shaft and bearings are also critical components of a vertical slurry pump. The shaft connects the motor to the impeller, transmitting the power necessary to move the slurry. Regularly lubricating the shaft and bearings can help prevent wear and reduce the risk of breakdowns. Additionally, monitoring the temperature of the bearings can help identify any potential issues before they escalate.

Proper maintenance of the seals is essential to prevent leaks and maintain the efficiency of a vertical slurry pump. The seals help prevent slurry from leaking out of the pump and damaging the surrounding equipment. Regularly inspecting the seals for wear and tear and replacing them as needed can help prevent costly repairs and downtime.

In conclusion, mastering the operation and maintenance of vertical slurry pumps is essential for ensuring maximum efficiency and performance. By regularly inspecting and maintaining key components such as the impeller, casing, shaft, bearings, and seals, operators can prolong the lifespan of their pumps and reduce the risk of costly breakdowns. Additionally, implementing preventative maintenance measures can help optimize the pump's performance and reduce energy consumption. By following the maintenance tips outlined in this guide, operators can ensure their vertical slurry pumps continue to operate at peak efficiency for years to come.

- Maximizing Efficiency and Performance of Vertical Slurry Pumps

Vertical slurry pumps play a crucial role in various industries, including mining, power generation, and wastewater treatment. These pumps are specifically designed to handle abrasive and corrosive slurries efficiently, making them an essential component in many processes. In order to maximize the efficiency and performance of vertical slurry pumps, it is important to understand their mechanics, operation, and maintenance requirements.

One key factor in maximizing the efficiency of vertical slurry pumps is proper sizing and selection. It is essential to choose a pump that is designed to handle the specific characteristics of the slurry being pumped, including its composition, size, and density. Additionally, the pump must be properly sized to ensure optimal performance and energy efficiency. Oversized or undersized pumps can lead to increased wear and tear, reduced efficiency, and higher operating costs.

Another important aspect to consider is the pump's design and construction. Vertical slurry pumps are typically constructed with high-quality materials such as rubber, polyurethane, or metal alloys to withstand the harsh conditions they are exposed to. The pump's impeller, casing, and shaft must be designed for maximum durability and wear resistance to ensure long-term performance.

Proper installation and operation are also critical in maximizing the efficiency of vertical slurry pumps. The pump should be installed according to manufacturer's recommendations, with proper alignment and support to prevent vibration and premature wear. Regular inspection and maintenance are essential to ensure the pump is operating at its best. This includes monitoring for signs of wear, leakage, and cavitation, as well as checking and adjusting impeller clearances and shaft alignments.

In addition to proper sizing, design, and maintenance, there are several operational considerations that can help improve the performance of vertical slurry pumps. One important factor is the pump's speed and flow rate. By adjusting the pump's speed and flow rate to match the requirements of the application, operators can reduce energy consumption and optimize efficiency.

It is also important to consider the slurry's characteristics when operating a vertical slurry pump. The pump should be adjusted to handle fluctuations in slurry composition, density, and viscosity to ensure smooth operation and prevent clogging or blockages. Proper monitoring and control of the pump's operation can help prevent damage and downtime.

In conclusion, mastering the vertical slurry pump requires a comprehensive understanding of its mechanics, operation, and maintenance requirements. By properly sizing, selecting, designing, and operating vertical slurry pumps, operators can maximize efficiency and performance, leading to improved productivity and cost savings in various industrial applications.

- Troubleshooting Common Issues with Vertical Slurry Pumps

Vertical slurry pumps are essential equipment in various industries such as mining, construction, and wastewater treatment. These pumps are designed to handle abrasive and corrosive slurries, making them crucial for the efficiency and performance of operations. However, like any machinery, vertical slurry pumps can encounter common issues that may affect their functionality. In this comprehensive guide, we will explore how to troubleshoot these common issues and ensure the optimal performance of vertical slurry pumps.

One of the most common problems that vertical slurry pumps encounter is clogging. Clogging can occur when the pump is handling a slurry with a high concentration of solids, causing blockages in the impeller or discharge pipe. To troubleshoot this issue, it is essential to inspect the pump regularly and clean out any debris that may be causing the blockage. Additionally, adjusting the pump speed or installing a strainer can help prevent clogging and ensure smooth operation.

Another common issue with vertical slurry pumps is leakage. Leakage can occur due to worn out seals or gaskets, causing a loss of efficiency and performance. To troubleshoot this issue, it is crucial to check the seals and gaskets regularly and replace them if necessary. Additionally, ensuring proper installation and alignment of the pump can help prevent leakage and maintain the pump's efficiency.

Furthermore, vertical slurry pumps may experience issues with overheating. Overheating can be caused by a variety of factors, including a lack of proper lubrication, excessive vibration, or a damaged motor. To troubleshoot this issue, it is essential to check the pump's lubrication system and ensure that all components are properly lubricated. Additionally, addressing any issues with vibration and inspecting the motor for damage can help prevent overheating and prolong the pump's lifespan.

In conclusion, mastering the vertical slurry pump is crucial for ensuring efficiency and performance in various industries. By troubleshooting common issues such as clogging, leakage, and overheating, operators can maintain the optimal functionality of their vertical slurry pumps. Regular inspection, maintenance, and proper installation are key to preventing these common issues and ensuring the longevity of vertical slurry pumps. By following the guidelines outlined in this comprehensive guide, operators can maximize the efficiency and performance of their vertical slurry pumps and avoid costly downtime.

Conclusion

In conclusion, mastering the vertical slurry pump is vital for ensuring efficiency and performance in various industrial applications. With over 20 years of experience in the industry, our company has honed its expertise in this critical equipment. By following the comprehensive guide provided in this article, you can maximize the efficiency and performance of your vertical slurry pump, ultimately leading to improved productivity and cost savings. Trust in our experience and knowledge to help you achieve optimal results with your vertical slurry pump. Thank you for reading and we look forward to continued success in the industry together.

Our professional slurry pump team is always At your services.

Contact: Ms.Serena Zhang

Tel: +86 13333119820

Email: sales@cnsmepump.com

WhatsApp: +86 13333119820

Add: 260# West Huaian Road, Shijiazhuang, Hebei, China. 050051.